How Machine Learning Can Benefit Your Supply Chain

Supply chains are going through some tough times right now. As the pandemic has put an enormous strain on already existing issues, many supply chains had to change their operating models altogether to keep the businesses running — no wonder that building resilience has become the top priority for supply chain executives.

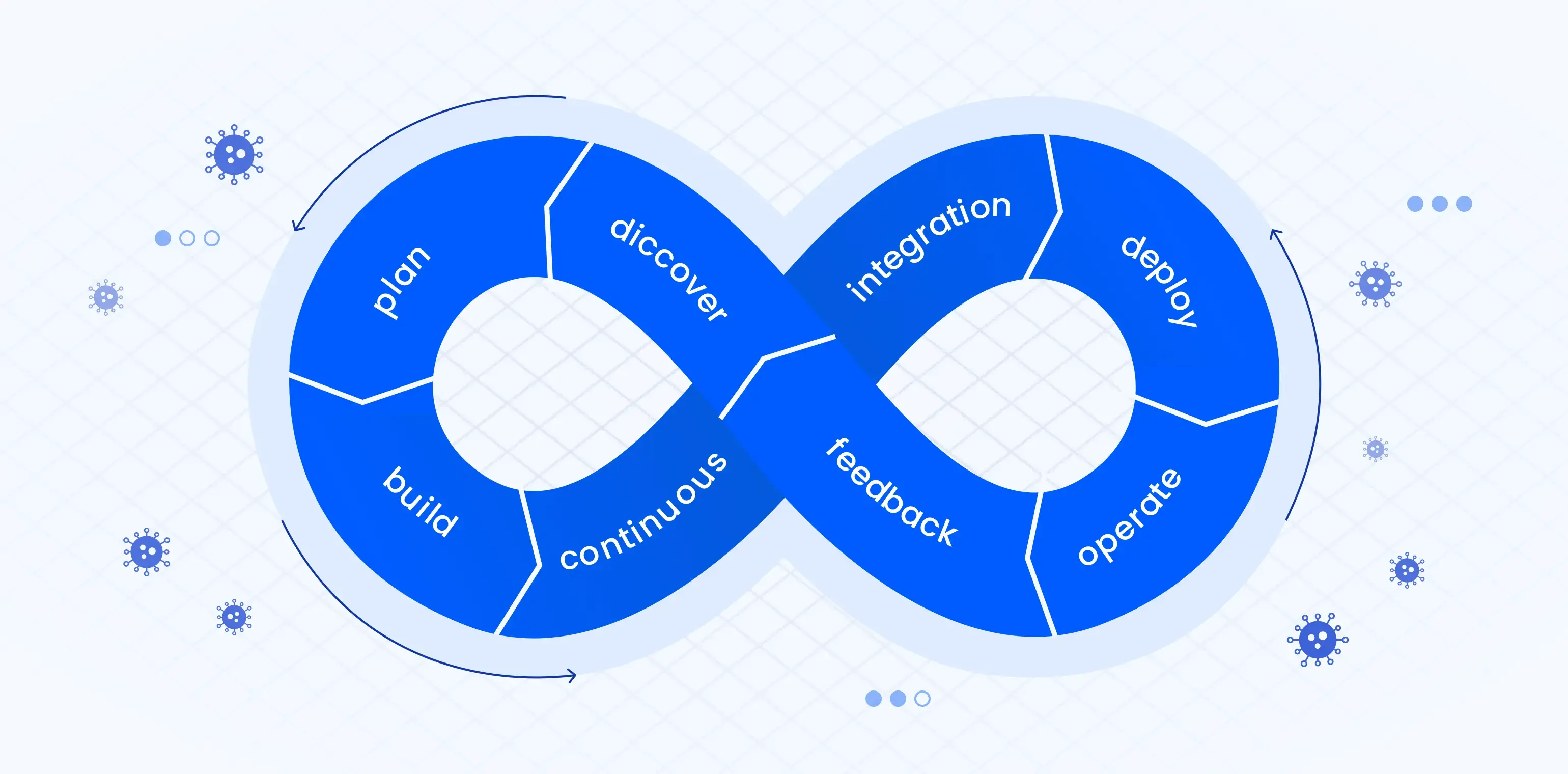

Eventually, supply chain resilience will only be reached through continuous optimization, extensive data analysis, and proper risk management. Manual data processing is virtually obsolete in terms of detecting patterns within a supply chain as it takes too much time and effort. This is where technology plays a crucial role. Machine learning and artificial intelligence tools can quickly recognize certain patterns or errors by analyzing multitudes of data. What’s more, the algorithms are constantly improving, providing plenty of possibilities for efficient supply chain optimization. Incorporating machine learning into your supply chain can provide you with valuable insights that lead to data-driven and proactive decision making.

How can machine learning be applied to a supply chain?

There are many dimensions and links in a complex supply chain environment that are prone to disruption. For this reason, machine learning and AI should be applied across multiple verticals.

Global supply chain optimization

Machine learning can improve many areas of a supply chain, but there are a few ultimate goals companies are trying to reach, including cutting costs, increasing profit margins, and reducing manual labor. To achieve these results and maintain them in the long run, supply chain executives need to make strategic decisions as impactful decisions are impossible without extensive data analysis and meaningful insight. First and foremost, machine learning and AI tools are meant to enable supply chain executives to focus on value-added work and strategic decision making.

Inventory management & fulfillment

The analytic and predictive capabilities of machine learning make it an excellent solution for inventory management. Many companies face challenges relating to over and understocking, data errors, and inefficiency when it comes to managing stock products. Since the online shopping market is soaring, there’s also a growing need to forecast sales volumes for multiple retail channels. How exactly is machine learning applied to inventory management, you ask? It predicts the demand. Algorithms detect reoccurring and new trends within the data volumes, producing accurate forecasts of how many products will you need for the season.

This prevents companies from buying too many products from suppliers and helps avoid delivery delays if there’s not enough stock. In short, demand forecasting enables a supply chain to be more flexible and resilient by allowing executives to quickly react and adjust.

Smart warehouse management

Keeping and maintaining warehouse facilities is costly — you definitely don’t want to overspend for inefficient use of space. Additionally, warehouses are mainly backed by facility workers and their manual labor, accompanied by lots of paperwork and human errors. Using machine learning techniques in warehouse management can reduce labor costs, eliminate operational issues, and help increase warehouse functionality. Deep learning algorithms can significantly improve the product arrival and delivery process, simplify documentation circulation, and automate many other processes.

It is no secret that a complex supply chain involves working with multiple warehouse locations. Machine learning can also help streamline operations, bridging the gap between all of these locations, ensuring all of your facilities remain connected and integrated.

Another common use of machine learning and AI in warehouse management is robotic devices. According to Tractica Research, the worldwide sales of robots for logistics management are anticipated to reach $22.4 billion by 2021. Retail giants like Amazon, are actively using collaborative robots alongside their human workforce to increase operational efficiency. It might seem like only a few industry leaders are able to use top-notch technology for optimizing their warehouses; however, the Deloitte 2019 Annual Industry Report states that more than 32% of supply chain professionals are actively using robotics and automation.

Customer service

Using machine learning is extremely beneficial to all aspects of customer service. It allows you to provide accurate delivery date estimates and predicts all potential issues that may arise while the shipment is in transit. As customer experience is now the holy grail for companies, machine learning tools can drastically enhance it.

Chatbots and virtual assistants are a great example of how deep learning can reduce tedious jobs for supply chain specialists and provide quick and clear communication to the customers. According to research by Accenture, more than 80% of customer service interactions can be handled by chatbots.

The potential of machine learning and AI in customer service is not just limited to bots. Companies like UPS use special algorithms to monitor more than 8 million social media posts in order to gain customer feedback and insights. This algorithm detects predetermined keywords and extracts patterns from the processed data.

Route optimization

Transportation is another crucial area of any supply chain that often consumes plenty of extra cost and effort if it’s not planned properly. Smart technologies analyze factors that affect transit times, like weather and road conditions, whether it be trucking, air freight, or sea transportation. Such route optimization can save vast amounts of transit time and consequently reduce overall transportation spending. For example, DHL saves 10 million gallons of fuel annually just because of its route optimization. Additionally, the shipping giant monitors 58 different measures of internal data, which allowed it to develop a deep learning tool for managing air freight. This enables the company to predict average transit time up to a week in advance.

Machine learning also makes logistics and transportation transparent and helps integrate them into the supply chain in order to quickly detect issues and react to them. Additionally, tech tools are extensively used for monitoring trucking conditions, which is essential for products that require climate control. Real-time updates surrounding temperature and humidity allows drivers to quickly fix any potential issues and avoid delivering spoiled shipments.

Final thoughts

Machine learning and AI are not just logistics industry buzzwords. They are powerful tools that can help companies cut costs, increase efficiency, and build supply chain visibility and resilience. What’s more, these technologies are becoming more and more essential for businesses that want to remain competitive. There are multiple uses and applications for machine learning and artificial intelligence in supply chains, but mostly it is beneficial for inventory and warehouse management, transportation, and overall business growth. Investing in innovative technology is a strategic and profitable decision for your supply chain’s long-term growth.