How to Optimize Freight Management: a Six-Step Plan

The majority of customers consider efficient service to be a key element of a positive customer experience. This is no surprise because time is valuable, and if users cannot get what they need at your place, they will go elsewhere.

Understanding growing business demands, entrepreneurs are changing their work approach by adopting innovation and technological development. Today, companies are increasingly using business process automation (BPA) solutions to reduce manual work, increase productivity, and establish more trustful relationships with customers.

Freight management software plays an essential role in the digital transformation of businesses. It helps optimize routes, reduce downtimes, and cut shipping costs. If you want to update your freight operations with the help of purpose-built tools, see how you can do it within a six-month plan.

Freight, Logistics, or Supply Chain Management: what’s the difference?

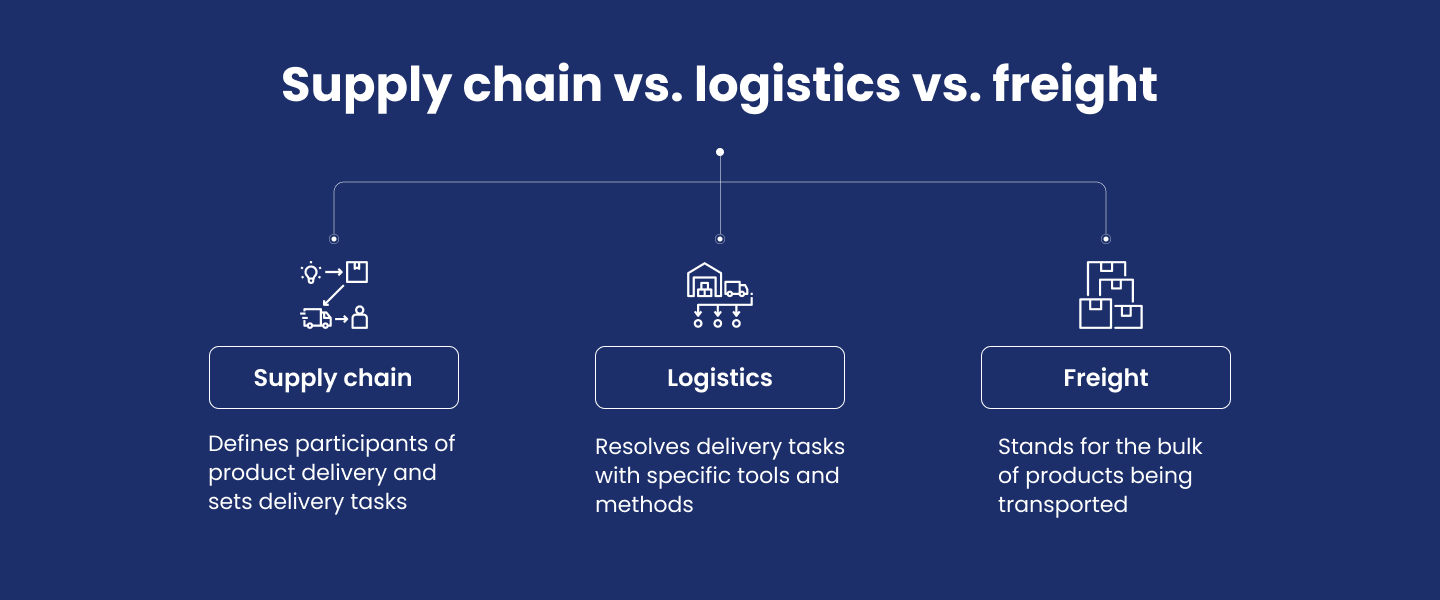

When it comes to building optimal routes, the terms freight, logistics, and supply chain are often used interchangeably. Even though these concepts are closely related, they are not the same.

Supply chain is the broadest concept. It identifies all parties participating in procurement, production, distribution, and consumption. Supply chain managers determine all receiving points before a product reaches the end consumer and set required deadlines.

Logistics goes hand in hand with the supply chain and determines how the product will move from one receiver to another. While the supply chain sets delivery tasks, logistics resolves them with specific tools and methods.

Freight means the transportation of bulk products by ship, train, plane, or truck. This term is often used together with supply chain and logistics because businesses deal with large quantities of goods and increasingly use freight management services.

The following example will help you to understand how supply chain vs. logistics vs. freight relate and differ.

Imagine that you are a retailer who sells craft goods on a marketplace like Etsy. When you receive an order, you have five days to produce the product and send it to the buyer.

Here is what you need to do to complete the order:

order materials from a supplier

receive materials and produce the product

send the product to the buyer

The above activities include three participants - supplier - producer - consumer - and define the supply chain.

Next, you need to decide how you will get materials and send goods. For this you:

check several delivery services

compare delivery speed

compare shipping costs

choose the best option

The above activities are the logistics considerations.

The parcel you will receive (materials) and send (ready product) stands for freight.

In this example, we analyzed an order from one buyer. But you may have orders from hundreds or thousands of customers. In this case, you will not be able to do without a freight management system (FMS) that will help you automate all the delivery tasks.

Benefits of a freight management system

A freight management system is a critical piece of the supply chain puzzle for any company looking to scale up its business. An FMS enables you to track and manage your goods as they move through the supply chain, from production to delivery. This not only saves you time and money, but also ensures that your goods are delivered on schedule and under budget. Some of the specific benefits of an FMS include:

Reduced shipping costs. The software suggests the most cost-effective delivery methods, so you can choose the best options from the speed/price perspective.

Improved shipping efficiency. FMS automates shipping lifecycle, so you reduce manual work and eliminate human errors.

Increased visibility of the supply chain. FMS gives you timely insights about your cargo location and allows transparent shipping tracking.

Enhanced customer service. Effectivefreight management solutions help serve customers faster, better, and in a more personalized way.

Quicker decision making. Freight management application offers the most optimal methods for cargo movement, allowing you to make quicker and more efficient business decisions.

How to implement a freight management system in six steps

Implementing freight and logistics software is a challenging task. However, if you have a detailed plan created by a mature development team, you can be sure that your efforts will bring excellent results.

Here are six steps to help you get started:

Step 1. Assess your current situation

What are your needs, and what system are you currently using for cargo management? If you already have freight brokerage software, audit it and identify its strong and weak points. Compare the costs of maintaining the system with the benefits you get from it. If the business value is minimal, direct your freight optimisation strategy to refactoring an existing FMS or creating a new one.

Step 2. Establish goals and objectives

What do you hope to achieve with shipment management software? Perhaps you want to identify the most time-consuming points on the way to the cargo journey. Or, probably, you want to reduce manual work and automate deliveries. Maybe, you aim to improve the quality of customer service by optimizing last mile delivery and route planning. Whatever goal you pursue, it must be clearly defined so that the developed FMS fully meets your business needs.

Step 3. Select the right system

There are many different types of freight management systems, so find one that fits your needs. If you are a startup and are only at the beginning of a logistics optimization journey, you may want to consider standard truck management solutions . Typically, ready-made truck management systems lack flexibility and customization opportunities, however they are more affordable for small companies because they pay a subscription fee rather than invest in freight TMS development. On the other hand, if you are a mid-sized company or a large enterprise, custom software will give you more flexibility for cargo management and allow you to achieve business optimization goals faster

4. Implement FMS

If you decide to develop freight software from scratch, it is better to book a call with a company with vast experience in developing truck management services. At the consultation, you detail your expectations of an FMS, and managers will select technologies and specialists to fit your budget. At Erbis, we always recommend starting a new project with a minimal viable product (MVP). By investing in basic functionality, you minimize the risk of failure and maximize the chance of producing high product-market fit.

When it comes to FMS, you can start with a web version that covers real-time cargo tracking, load planning, route management, price comparison, and shipment conditions control. An experienced team of three specialists (backend developer, frontend developer, QA engineer) can implement such a project in three to six months. Using cloud technologies, they will enable users to instantly access the service, regardless of place and time of their stay.

5. Train your team

Your employees should know all the capabilities of the freight management system and be able to get the most out of it. Therefore, when the product is ready, spend time on training sessions, explain why the FMS is in place, and what effect you expect to get from it. Pay special attention to security issues. Make sure to create different authorization roles and teach users how to prevent data leakage.

6. Measure success

A freight management system should be able to track and measure the success of your supply chain operations. With accurate data, you can identify areas where improvements are needed and make changes accordingly. You should also set key performance indicators (KPIs) to track the progress of your freight management system. This will help you determine whether or not your system is meeting your business objectives.

Conclusion

In order to stay competitive in today's business landscape, it's essential to optimize every process within your company. An intermodal management system is no exception. By taking the time to implement freight management software and measure its success, you can ensure that your company is running as efficiently as possible.

At Erbis, we have vast experience in building various logistics solutions. We help startups and enterprises to optimize routes, automate deliveries, and set up transparent order tracking. If you are looking for a reliable technology partner to make a carrier management system or just need expert advice, get in touch. We'll be happy to help.